Polymer Chemistry Notes 7th Science Lesson 14 Notes in English

7th Science Lesson 14 Notes in English

14] Polymer Chemistry

Introduction:

Polymer chemistry has a positive impact on your everyday life. Many of the materials you use are linked to polymer chemistry. When you get ready for school, you wear clothes, shoes, brush your teeth and take a school bag. Did you ever ask yourself what these items are made of? They are created from fibres. Fibres are made up of long chains of natural or synthetic polymers.

As a society, we are consuming more and more. The more things we buy the more things we throw away. 30 years ago, most of the waste in Tamil Nadu was biodegradable or easily recyclable. Today it is more complex. Many of the materials we use are non-biodegradable and difficult to recycle. For example, in the past people used many natural materials such as cotton, silk and jute fibres. Today we use a lot of synthetic materials such as plastics. In this lesson you will learn about polymers, different types of fibres, plastics and the waste we produce and how we should manage it.

What Are Polymers?

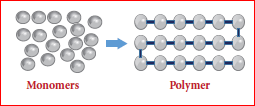

The word ‘Polymer’ is of Greek origin. ‘Poly’ means many and ‘mer’ means basic smaller unit. Polymers are very long chains made of repeating smaller molecules called ‘monomers’ that are joined together

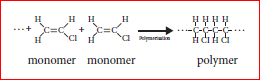

By covalent bonds and the process is called polymerization. The diagram below shows how repeating monomers join to form a polymer:

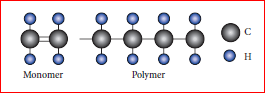

Polyvinyl Chloride (PVC) is a common plastic used for water pipes. The monomer and polymers of PVC is shown below.

Polymer:

Polymers can be classified into natural and synthetic polymers. Can you imagine that your body produces and you are made up of natural polymers? The most familiar polymers that we use in our daily life are man-made and synthetic.

Natural Polymers:

Natural polymers are found in living systems that include proteins and carbohydrates in our bodies and cellulose in wood and paper. They play a very important role in living things to provide structural materials and molecules needed for life processes.

Protein polymers are made from amino acid monomers (20 different kinds of amino acids). Different combinations of the amino acid monomers create many different protein polymers. Examples of protein polymers include DNA, enzymes, silk, skin, hair, fingernails, feathers and fur.

Examples of carbohydrate polymers include cellulose, chitin and lignin found in plants. Cellulose is made of sugar molecules and is the main component of cotton used in clothing. Chitin is found in the cell walls of fungi such as mushrooms and exoskeletons of insects such as crabs and spiders. Lignin consists of a network of polymers and is important in giving structure to plants.

Synthetic Polymers:

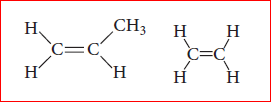

Synthetic polymers are man-made polymers produced by using raw materials from petroleum oil and gas. Plastics are synthetic polymers. When oils and gases are processed to make petrol, ethylene and propylene monomers are removed as by products. We have already seen that polymer such as the Poly Vinyl Chloride (PVC) is made up of many monomers joined together. Ethylene and propylene are the building block monomers that make up many different types of plastics.

Propylene and Ethylene

Based on the nature of the monomers, the way they are arranged in the polymer and the characteristics of final polymer.

There are grouped into different categories such as fibres, plastics, proteins. Let us study about few of them in the following sections.

Fibres:

We wear clothes, use bags, rope, blankets, etc. in our daily life. They are made of fibres. Once upon a time, people used natural fibres such as cotton and wool. Nowadays, we use a lot of synthetic fibres. All natural and synthetic fibres are polymers.

Observe the difference between the natural and synthetic fibres:

Natural Coconut Rope vs. Nylon Fishing rope

Natural and Synthetic Fibres:

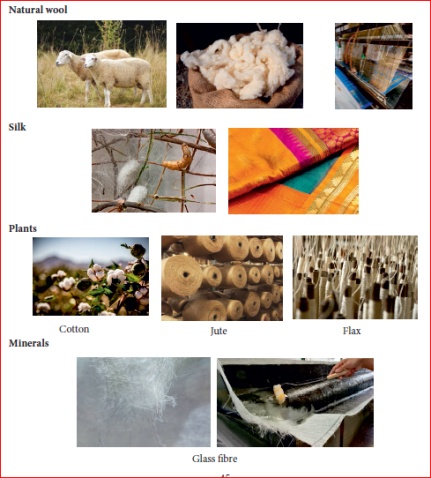

Fibres are long strands of polymers interwoven to form linear, string-like structures. Fibres that are obtained from plant or animal sources are called natural fibres. Examples include cotton, coconut fibre, hair, wool and silk. Fibres that are made using raw materials from petroleum are synthetic fibres. Examples include polyester, acrylic and nylon. Historically, humans used natural plant fibres and animal fur for shelter, clothing and protection from the weather. Today, a large variety of natural fibres are still grown and processed such as cotton, silk, and wool. Natural fibres can be spun into filament, thread or rope. Then they can be woven, knitted, matted or bonded and are used to make clothing, containers, insulation material and many other products we use in our daily life. Three main sources of natural fibres are : (i) Animal (e.g.) wool and silk.

The discovery of making synthetic fibres out of petrochemicals has replaced the use of many natural fibres. Synthetic fibres such as nylon, polyester and acrylic are used to make many different plastic items you use in your daily life such as clothing, blankets, tooth brushes and stuffing in cushions.

Types and Uses:

Silk: Natural Fibre:

Natural silk fibres are obtained from boiling the cocoons of silk worms from specific species of moths. There are four types of natural silk: Mulberry silk, Tasar silk, Muga silk and Eri silk. Most of the mulberry silk worldwide is produced in India. Silk is one of the strongest natural fibres and has many uses such as clothing, carpets and parachutes.

Rayon: A Semi-synthetic Fibre:

In the 19th century scientists were successful in producing the first artificial silk known as rayon. The first rayon factory in India was established in Kerala in 1946. Rayon is a man-made fibre, but it is not considered fully synthetic as it is made out of natural cellulose collected from wood pulp.

The cellulose that is collected from wood or bamboo pulp is treated with several chemicals. First sodium hydroxide is added followed by carbon disulphide. The cellulose dissolves in the chemicals added to it and produces syrup called Viscose. Viscose is forced through a spinneret (a device made of metal plates with very tiny holes) into a solution of dilute sulphuric acid. This produces silk-like threads that are cleaned with soap and dried. This new fibre is called rayon.

Some types of rayon are made from the short cotton fibres left on cottonseeds after ginning. Rayon is cheaper than silk, can be woven like natural silk fibre and can be dyed in a wide variety of colours. It can be mixed with cotton to make bed sheets or with wool in the production of carpets and home furnishing products. Rayon is also found in sanitary products, diapers, bandages and gauze for dressing wounds.

Nylon: Synthetic Fibre:

Nylon is the first fully processed synthetic fibre. It was popular during the Second World War for the use of parachutes and rope materials for climbing. Nowadays, nylon has replaced natural silk in many textiles, and has become one of the most commonly used synthetic fibres.

Nylon fibre is strong, elastic and light. It is lustrous and easy to wash, which has made it popular for the clothing industry. We use many products made from nylon such as socks, ropes, tents, toothbrushes, car seatbelts, sleeping bags, curtains, etc. Nylon thread is actually stronger than a steel wire.

Polyester and Acrylic:

Synthetic Fibres:

Polyester is another synthetic fibre. It can be drawn into very fine fibres that can be woven like any other yarn. Polyester is sold in the name of polycot, polywool, terrycot, etc. Polycot is a mixture of polyester and cotton; Polywool is a mixture of polyester and wool. PET (Polyethylene Terephthalate) is a very familiar form of polyester. It is used for making water and soda bottles, utensils, films and wires amongst many other useful products. Many of the clothes we wear are made out of polyester fibres. Fabrics made from this fibre do not get wrinkled easily and are easy to wash making polyester fabrics suitable for dress materials.

We wear sweaters and use shawls and blankets in the winter. Many of these are not made from natural wool although they appear to resemble wool. These are prepared from another type of synthetic fibre called acrylic. The wool obtained from natural sources is quite expensive, where as clothes made from acrylic are relatively cheap because they are a by product of the production of plastics. They are available in a variety of colours. Synthetic fibres are more durable and affordable which has contributed to their widespread use.

Advantages of Synthetic Fibres:

Do you ever think about why some of your clothing does not need ironing and looks bright and colourful for many years? This is because they are made from synthetic fibres such as polyester and the advantages are that they do not wrinkle easily and they keep their colour and brightness for a much longer time than natural fibres such as cotton.

A lot of materials such as fishing nets are made from synthetic fibres. One of the main advantages of using synthetic fibres such as nylon, is that they are stronger than many natural fibres such as silk or wool. For example a trampoline is made of woven synthetic fibres. These fibres are strong and elastic which gives it the properties to bounce.

Drawbacks of Synthetic Fibres:

We have already learned that it is safer to use cotton clothing instead of synthetic clothing when a person is cooking or working in a laboratory. This is because one disadvantage of synthetic fibres such as polyester is that they are not heat resistant and catch fire easily. In summer it is better to wear clothing that is made out of cotton materials rather than synthetic. This is because most synthetic fibres absorb very little moisture and do not allow air circulation making them hot and uncomfortable to wear.

If you could recall that we already found out that synthetic fibres are made out of petrochemicals and last in the environment for a very long time. The disadvantage is that they break down into very small pieces called microplastics which cause pollution to soil and water bodies such as rivers, lakes and oceans.

Plastics:

Ask yourself what is the first plastic thing you touched today! Maybe it was your alarm clock or the filling in your pillow or the synthetic clothes that you were wearing. Almost everything around us today is plastic. You have seen water and oil in polythene pouches. Right! In the past, people used to bring milk, oil and other liquids from a shop in vessels made of materials such as metal and glass. Think about what the containers,

buckets, mugs, chairs and tables used in the past were made of? What do we use today to make many of these products?

Plastic as a material has taken over and replaced metal and wood which were previously used. Plastics have also replaced many glass items. If we continue to write the list of everyday items that are made of plastic, it will be endless! Why is plastic so popular? What are the different uses of plastic? What are the various types of plastics? Let us now learn about plastics:

Plastics have helped us to make advancements in technology, building, healthcare, transport and food safety. Plastics have completely occupied our life because of their characteristic qualities. Plastics have many positive qualities such as lightweight, strong and they can be moulded into complex shapes. They are also flexible and waterproof and some plastics are even UV resistant. Plastics are also cheap and convenient for us to use. Now that you have discovered why plastics are so popular, let us find out more about the different uses of plastics.

Health care items:

Items that are waterproof or UV resistant

Uses of plastics:

There are different types of plastics that are excellent materials when they are used for the right application. For example, let us take a syringe that is made from a type of plastic called polypropylene. These syringes do not have to be sterilized and reused; hence they provide a high standard of hygiene and eliminate the risk of spreading diseases.

Just as plastic is a material that can be used for a good application, it can also be used for the wrong application. Think about the different items you use that are plastic. For example, a simple article such as a thin plastic carry bag. You use this bag for a very short time and then throw it in a dustbin. Many of these carry bags

do not get recycled and they litter and pollute our environment for a long time.

If you want to learn more about plastic which is used for the wrong application then you can refer to the Government of Tamil Nadu’s ban on one-time use and throwaway plastics (Environment and Forests Department, T.N. G.O. No: 84, dated 25/06/2018, with effect from 1st January 2019).

Types of plastics:

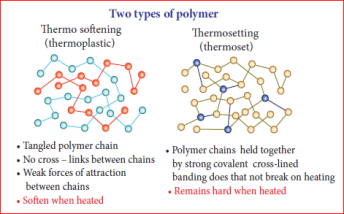

The plastics we use in our daily life are also made up of polymers. All plastics do not have the same type of arrangement of units. In some articles, the arrangement of a monomer is linear, and in some other items, the arrangement of articles is cross-linked. Depending on the type of arrangement, we have two main types of

polymers – thermoplastics and thermo-set. Let us see what these are!

Thermoplastics: Polyethylene (also called polythene) is an example of a plastic. It is used for making polythene carry bags which are commonly used. When you burn a polythene carry bag, it melts and turns into liquid along with the production of an offensive odour, a bright flame and soot. Another example is a PET (Polyethylene Terephthalate) bottle, when we fill it with boiling water, it gets deformed. Plastics which can be easily softened and bent when heated are known as thermoplastics. These plastics can be modified and turned into another plastic item through the process of recycling.

Thermo-set: On the other hand, there are some plastics, which once they are moulded, cannot be softened through heating them. These are called thermosetting plastics. Bakelite and melamine are some examples of thermosetting plastics. Bakelite is a poor conductor of heat and electricity. It is used for making electrical switches and handles of various utensils. Melamine resists fire and can tolerate heat. It is used for making floor tiles and fabrics that resist fire.

Example of thermoplastic: PET water bottles

Example of thermo-set plastic: electrical switches

Resin code of plastics:

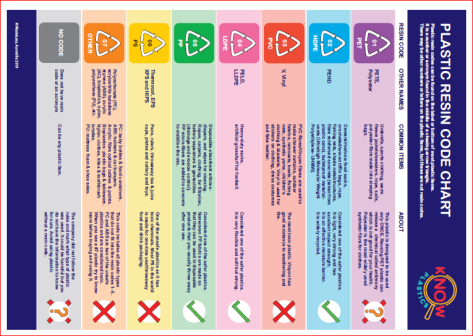

Now that you have learnt about the differences between Thermoplastic and Thermosetting polymers, let us find out more about the different types of plastics that you use in your daily life. Plastics are very useful in our daily life but some types contain dangerous chemicals.

Did you know that there are many different types of plastics?

You can tell these plastics apart by searching for a resin code. The resin codes are a universal way of categorising different types of plastic, which helps us separate plastics so that it is easier to recycle them. How can you identify the resin code? Where can you find the resin code on a plastic item?

Look at the chasing arrow triangle-shaped symbol on the bottom of a bottle, on the brand label sticker or on the lid of a container. What number is marked in the centre of the triangle? What letters (acronym) are below this? This is what we call a resin code.

If the number is 1 within the chasing arrow triangle and/or has the acronym PET or PETE, then it is a type of plastic which is called PET. Now that you have found out that the bottle has a specific resin code, let us see what gives the bottle and other plastic products certain qualities. Different chemicals (additives) are added to plastic to give them various qualities and characteristics, for example flexibility, strength, softness or transparency. There are some chemicals that are used in plastics that are dangerous for our health, animals and the environment. For example, Polyvinyl Chloride- PVC resin code #3 has heavy metals such as cadmium and lead which are toxic chemical which are harmful to your health. Polystyrene- PS resin code #6 has styrene which is a toxic chemical known to cause cancer.

Look at the resin code chart on the previous page to find out more about the different types of plastic, what are common items and which plastics are safe and unsafe for us, animals and the environment.

Look at the resin code chart to find out more about the different types of plastic, the common items and the plastics that are safe and unsafe for us, animals and the environment.

Impacts of plastics:

Plastics are cheap, light weight, strong and durable and have contributed to a range of advances and benefits to our modern life. But the increase in the use of plastics, particularly the one-time use and throwaway plastics has serious impacts on the environment, animals and our health.

We have seen garbage dumps with different plastics. One big problem with plastics is that they do not decompose or biodegrade. This leads to large amounts of waste that will not disappear and end up accumulating and polluting the environment.

A lot of one-time use plastic such as polythene bags and food packaging that are thrown away are responsible for littering the environment and clogging drains. Standing water breeds mosquitoes that can spread diseases such as malaria, dengue and chikungunya and also lead to flooding.

Why do you think some animals eat plastic? Many animals confuse plastic for food and eat it by accident. When left over food is thrown away it is often packed in plastic. Animals smell the leftover food and eat the plastic by accident. For example animals in urban areas, particularly cows, often eat polythene plastic bags by accident as they contain food waste. Can you imagine the consequences?

A lot of the plastic waste we use such as plastics bags, bottles and straws end up in the oceans. Plastics in the ocean are exposed to sunlight, water and the physical movement of the waves, which breaks it down in tiny pieces called microplastics. Some microplastics are also found in household products. Examples are microbeads that can be found in toothpaste, face wash and body scrubs. Microbeads are washed down in drains and end up in the soil, rivers, lakes and the ocean Microbeads are washed down in drains and end up in the soil,

rivers, lakes which cause pollution.

Microplastics in the Ocean

Many birds eat plastic items and small pieces of plastic, which are covered in algae. Once in the stomach of animals, plastics cannot be digested and this decreases the amount of space for food and can lead to starvation. In 2015, plastics were found in 90% of seabirds.

We have already read that Government of Tamil Nadu has banned one-time use and throwaway plastics such as plastic carry bags, plates, straws and water pouches. This is an indication that important efforts are taking place to reduce negative consequences of plastics on the environment.

PLA Plastics:

Can you see how much plastic litter pollutes our environment? How nice would it be if a material that had similar qualities to plastic could be biodegradable, be absorbed by the soil and give nutrients to the soil!

Yes, scientists have thought about alternatives to synthetic plastics and have found Poly Lactic Acid (PLA) –a substitute for some types of plastics. Poly Lactic Acid or polylactide is compostable and bioactive thermoplastic. This polymer is obtained from plant starch such as corn, sugarcane and pulp from sugar beets. PLA is a biodegradable material. It is useful for making food packaging, garbage bags and disposable table ware.

PLA food containers Tea bags

Various methods of disposing plastics:

Plastics are everywhere! Our increasing consumption and production of plastic waste needs a solution. Let us find out more about how and where plastic waste is disposed of and the better methods of disposing plastics.

Organic waste such as the peels of vegetables, fruits and food remains can get broken down by bacteria in the soil to create a rich source of nutrients in the form of compost. A material that gets decomposed through natural processes and action by bacteria is called biodegradable.

Plastics do not decompose by natural processes and action of bacteria and are therefore not biodegradable. It is important for us to separate our biodegradable and non-biodegradable waste and dispose of

them separately. A lot of the plastic produced globally is designed to be used only once and thrown away, creating a large amount of plastic waste. Plastic waste ends up being recycled, incinerated, land-filled, dumped or ends up littering our environment. It is estimated that from all the plastic waste ever produced, 79% is in landfills, dumps or in the environment, 12% has been incinerated and only a small 9% is recycled.

Let us learn more about what happens with the plastic waste. One way to look at plastic disposal is the 5R Principle – Refuse, Reduce, Reuse, Recycle and Recover. We have already learned about the waste pyramid and how the different methods of waste disposal can be seen in terms of the best option to the least favourable in this order: Refuse (Avoid), Reduce, Reuse, Recycle, Recover (Compost and Incinerate) and Landfill.

Refuse (Avoid):

The best thing to do is to avoid using plastic products. One-time use throwaway plastics can often be avoided. For example, we can carry cotton or jute bags when we go shopping and say no when a shopkeeper offers us a plastic bag.

Reduce:

Reducing the amount of plastic we use is important. Before buying a plastic product we can check to see if there are any substitutes or alternatives that can be used. If we use fewer plastics, we will create less plastic waste. However, even if we try to reduce the amount of plastics we use and throw away, it is impossible to stop using plastics completely.

Reuse:

If possible products made of plastics can be used again and again. For example, if we have a plastic bag in good condition, instead of throwing it away we can use it again the next time we go for shopping. If we have a plastic product and if you do not feel like using it again, we can give it to others instead of throwing it out.

Recycle:

It is better to recycle plastic waste. Separating plastic waste and making sure it gets recycled is good as it turns waste materials into something new. Then it will not be thrown away in landfills, open dumps or ending up as litter in the environment. Many thermoplastics can be recycled. They can be softened by heating and can be made into another article by recycling, but thermosetting plastics cannot be recycled. Recycling of plastics

is challenging and it is important to know that plastics cannot be recycled forever. There are so many different types of plastics, which are often mixed together making it difficult to separate them back into the original material. Every time plastic is melted and recycled it loses quality, this is called ‘downcycling’. Recycling of plastic waste cannot be the only solution to plastic pollution.

Recover (Compost And Incinerate):

Solid waste can be converted into resources such as electricity and compost through thermal and biological means. Burning plastics in a large furnace or in the open is bad for the environment. Open burning releases toxic pollutants into the air and soil, which are harmful to our health, animals and the environment. Burning plastics at high temperatures in incinerators and trapping the gases and collecting the toxic ash is widely used to produce energy. This is often seen as a positive way to deal with plastic waste. However, burning plastics releases super toxic gases, and the remaining ash contains toxic chemicals and heavy metals. Burning of plastics is not a good solution, as we end up wasting non-renewable resources and produce super toxic chemicals that are difficult to store or dispose safely.

Compost your organic waste

Open burning and incineration:

Landfill:

Plastic waste often ends up in landfills that are huge holes where waste is buried to keep it separate from the environment. This is the most common way for plastics to be disposed of around the world. Plastics make up 7-13% of waste that is sent to landfills on a global scale. Plastics in landfills can still lead to pollution of the air, soil and groundwater. Over time landfills can degrade, and the toxic chemicals in certain plastics can leak out into the environment.

Biodegradable plastics:

The concept of biodegradable plastics or bio-plastics was first introduced in the 1980s. Based on the nature of degradation, there are two main types of plastics: degradable plastic and compostable plastic.

Degradable plastics are made from petroleum oil or gas which is the same as conventional plastics. The difference is that they have a chemical or additive added to them to make them breakdown faster than conventional plastics when they are exposed to sunlight, oxygen or water. What do you think will happen to degradable plastics? Degradable plastics breakdown into tiny pieces called micro-plastics and these stay in our environment for a very long time. It is very important to understand that degradable plastics do not breakdown

Completely in the environment! Scientists have found that micro-plastics in the ocean are really bad and it is likely that these tiny pieces in the soil are also harmful.

Compostable plastics are derived from renewable resources such as corn, sugar cane, avocado seeds or shrimp shells. Compostable plastics can be broken down completely by microbes and turned back into food for plants carbon dioxide, methane, water and other natural compounds.

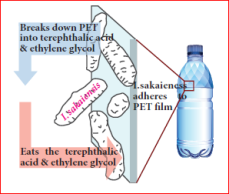

Plastic Eating Bacteria:

In 2016, scientists from Japan tested different bacteria from a bottle recycling plant and found that Ideonellasakaiens is 201-F6 could digest the plastic used to make single-use drinks bottles that are made of polyethylene terephthalate (PET). The bacteria works by secreting an enzyme known as ‘PETase’, that breaks down plastic into smaller molecules. These smaller molecules are then absorbed by the bacteria as a food source. The working of the enzyme is diagrammatically shown below:

Although the discovery of the bacteria breaking down plastics is seen as a potential solution to the plastic pollution – it is still very complex! A big issue is the scale of the plastic pollution problem. We consume and produce such large quantities of plastics and this is only increasing. The scale of the bacteria breaking down plastics is much slower and will therefore not solve the crisis we are facing.

Another limitation is that it is restricted to PET resin code #1 plastics, which currently is one of the most recyclable plastics worldwide. It will not be a feasible solution to the issue of the large quantities of non-recyclable low-grade plastics which are polluting the environment. That is why it cannot be the solution to plastic pollution on its own!

Glass – Types And Uses:

Glass can be found wherever we look; a glass window or glass mirror or glass light bulb. Glass is one of the world’s oldest and most versatile human created materials. Glass is the only material that can be recycled over and over again without losing its quality. Glass is bit of a riddle. It is hard enough to protect as, but it shatters with incredible ease. It is made from opaque sand, yet, it is completely transparent. Most surprisingly, it behaves like a solid material, but it is also a sort of weird liquid in disguise!

Glass is prepared by heating (SiO2) silicon-di-oxide until it melts, say to about 1700◦C and Sodium Carbonate is added to it. Then it is cooled down really fast. When SiO2 silicon-di-oxide melts, the silicon and oxygen atoms break out of their crystal structure. If we cooled it slowly, the atoms would slowly line up back into their crystalline arrangement. But if we cool the liquid fast enough, the atoms of the silica will be halted in their tracks, they won’t have time to line up, and they will be stuck in any old arrangement, with no order to the arrangement of the atoms. We call materials like this as amorphous. At this stage, glass is linear in arrangement inorganic in nature and has a structure very similar to glass and they are considered as polymers.

In a commercial glass plant, sand is mixed with waste glass (obtained from recycling collections), soda ash (sodium carbonate) and limestone (calcium carbonate) and heated in a furnace. The soda ash reduces the sand’s melting point and produces a kind of glass that would dissolve in water. The limestone is added to stop that happening. The end product is called soda-lime-silica glass. It is the ordinary glass we see all around us.

Usually, other chemicals are added to change the appearance or properties of the finished glass. For example, iron and chromium based chemicals are added to the molten sand to make green-tinted glass.

Oven-proof borosilicate glass (widely sold under the trademark PYREX) is made by adding boron oxide to the molten mixture.

Adding lead oxide makes from a sandwich or laminate of multiple layers of glass and plastic bonded together.

Toughened glass used in car winds hields is made by cooling molten glass very quickly to make it much harder.

Points to Remember:

- Fibres are long strands of molecules interwoven to form linear, string-like structures that can be woven, knitted, matted or bonded.

- Fibres can be natural or synthetic.

- Our increasing consumption and production of waste has negative impacts on humans, animals and the environment.

- Nylon is a synthetic fibre made from petrochemicals oil and gas.

- Polycot is a mixture of polyester and cotton, Polywool is a mixture of polyester and wool.

- Synthetic fibres melt on burning while cotton fibres catch fire on burning.

- Polymers are very long chains made of repeating smaller molecules called monomers that are joined together with different types of bonds.

- Plastics that get deformed easily on heating and can be bent are known as thermoplastics.

- Plastics that do not get deformed easily on heating and cannot be bent are known as thermosetting plastics.

- There are many different types of plastics. Some of which are safe or unsafe for us. We can find out what type of plastic an item is by identifying the resin code or acronym found on it.

- Poly Lactic Acid or polylactide is a biodegradable and bioactive thermoplastic.

- The management of plastics can be considered by the 5R Principle – Refuse, Reduce, Reuse, Recycle and `Recover as well as to Landfill.

- Ideonellasakaiensis 201-F6 is a bacterium discovered by scientists that digests plastic resin code #1 PET used to make single-use drinks bottles.

DO YOU KNOW?

Nylon is very strong and can be used for rock climbing!

Nylon is a plastic polymer made of chemical units called polyamides. Olyamides are made with monomers – hexamethylenediamine and adipic acid. Solid chips of these polyamides are melted and forced through a heated spinneret which has very, very tiny holes.

Parachute mountaineer

Synthetic fibres are made from the by products of processing petroleum oil and gas. You will learn about fractional distillation of petroleum in your higher classes.

It is estimated that every year we use a trillion plastic carry bags (2 million a minute) around the world and out of which only 1 to 3% are recycled.

Plastic has been around for less than 200 years. Edmund Alexander Parkes was the creator of the first plastic called ‘Parkesine’.

Edmund Alexander

We have seen that synthetic clothes are made from plastic. Every time we wash synthetic clothes, small fibres called microfibers escape and end up in the soil, streams, rivers and oceans.

Dangerous pollution called Persistent Organic Pollutants (POPs) floating in the ocean sticks to these small pieces of plastic making them toxic. Marine animals such as shrimp and fish often eat micro-plastics, confusing them for their natural source of food. The toxins build up in these animals and move up the food chain and can end up in our bodies. Micro-plastics can be found in the food we eat, the water we drink, and the air we breathe.